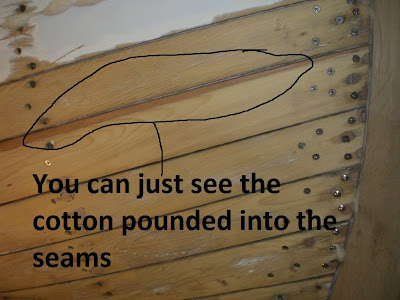

On a wooden boat, once you have the planking finished the boat

will still sink unless you “calk” and “pay” the seams. Calking is the act of

pounding cotton or oakum into the seams and paying is applying a compound to

fill the seams until the bottom is smooth. Now that the planking was done it

was time to start putting cotton into the seams. These are the tools of the

trade for a caulker. A mallet, calking iron and for me, a calking wheel.

|

| The mallet isn't a true "calking" mallet but it worked for me |

|

| I put a line on the calking iron to show me how deep I could go. |

You

take a rope of loose cotton and carefully work it into the seams then use the

roller to force it smoothly down into the seams.

|

| The cotton must be looped into place as you go across the seams. this alows you to add tighter loops (more cotton) or to stretch out the loops (less cotton). |

|

| You can just see the looping of the cotton in the seams |

|

| rolling the seams |

Afterwards, you use the

calking iron to set the cotton into the seams by pounding it gently but firmly

into place.

|

| Setting the coton with the calking iron. |

When I finally got all of the cotton into the seams, I put rubber

paying compound into the seams and filled all of the screw holes.

|

| Seams filled, holes filled ready to sand and paint. |

Ginger was now ready to sand and apply paint.

No comments:

Post a Comment